Pros

Setup is flawless

App is excellent

Amazing quality

Well designed

Cons

Filament waste could be an issue

The “poop flinger” is not good design

Editor’s note, May 15: Early versions of this printer were recalled due to a potential hazard with the print bed cable. My review unit showed no sign of the fault as it seems to happen only in specific circumstances. You should be free to purchase a new A1 without this issue from now on.

It’s been an amazing few years for 3D printing. The advent of a new breed of fast 3D printers that can offer superb quality at a reasonable price has opened the door to many new people. These printers are technically excellent while being easy to use by people without technical ability.

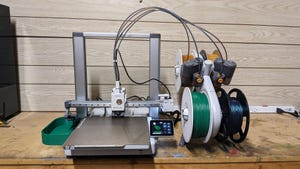

The A1 Combo is perhaps the best example of a modern 3D printer that I’ve seen. It is — and I say this with no hyperbole — the best consumer 3D printer I have ever used, and it’s as close to a perfect 10 as a product can be. Only a few small issues keep it from that perfect score, and none of them should deter you from getting one.

James Bricknell/CNET

The A1 required no technical skill to put together. If you have ever set up a paper printer or put together a floor lamp, you have the skill needed to set up this 3D printer. All it took was to remove a plastic cover, put the base in place on the gantry and screw the screws into the holes marked in green. The final part was to connect some plastic tubing and the power from the AMS color system and the printer itself. Incredibly simple.

The software setup is almost as easy. Bambuslicer is simple to download and not too difficult to use, and the Bambu Handy app is clear and easy to follow. I love a good companion app, especially when it isn’t flooded with advertisements. Bambu Handy allows you to monitor the print as it happens — it can even record time lapse as the model prints — and lets you browse Bambu Lab’s Makerworld, a repository of models you can download and print.

Bambu Lab A1 specifications

Build volume (mm) 256 x 256 x 256Nozzle type Quick Swap stainless steelMax nozzle temperature 300 deg CBuild plate max temperature 100 deg COfficial max speed 500mm/sTypical speed 200 – 300mm/sSupported material PLA, PETG, TPU, PVAConnectivity Wi-Fi, USBSlicer Bambu Slicer

While the A1 Combo at $549 is my recommendation, it’s possible to buy them separately. The A1 is a solid printer on its own and is perhaps the best budget 3D printer around today. Its $400 price tag makes it a little more expensive than some of the others in that class, but it’s still worth the price. The AMS Lite is a further $250, so while you can buy them separately, it’ll cost you an extra $100 in the long run.

The A1 specs are on par with the current crop of best fast 3D printers. The layout is Cartesian — the bed moves forward and back as the model prints, instead of CoreXY — the bed moves only up and down – like the company’s other printers (the P1S and X1 Carbon). The print volume is 256 by 256 by 256mm with an official print speed of 500 millimeters per second. At no point can this printer actually print at that speed though. The fastest it can go without looking terrible is around 300mm/s, which is still faster than a lot of the competition.

Quality without compromise

James Bricknell/CNET

Quality and speed are often at odds. The faster you go with a 3D printer, the more the quality suffers, and this has been true for the last decade. Bambu Lab helped change that premise with the X1 Carbon and P1P and has continued the trend with the A1 mini and now the A1. You can now get the same quality print from this $500 printer at 300mm/s as you would have got from a $900 machine at 75mm/s three years ago. It’s an amazing leap, and one that I welcome.

The A1, even without the AMS, is capable of stunning prints at high speed. I found the sweet spot to be around 200mm/s for the best quality. You can go faster, but if the model is tall, you run the risk of it shaking off the build plate or if you’re printing in color, faster speeds can cause layer skipping. As you can see from the Aztec dragons from Fotis Mint, the details stand out in sharp relief. I’ve printed in excess of 50 models on this machine by now and they are almost universally excellent.

The A1 also has quick swap nozzles that can help you print even faster. With a 0.6mm nozzle instead of the standard 0.4mm, you can push more plastic through in a hurry. There are even 0.8mm nozzles that you can use to make strong parts that don’t need to look pretty and all the nozzles take a few seconds to change. It’s another way the A1 feels fast more user friendly than before. You no longer need a wrench and risk breaking parts to remove a nozzle. You just unclip it, throw it away and replace it.

Bring color into your life

James Bricknell/CNET

The A1 is a good printer on its own, but the AMS Lite system that comes with the combo is what elevates the whole to a near-perfect product. It’s also, interestingly enough, the biggest reason it isn’t a perfect machine.

AMS stands for Automatic Material System and it’s what lets you print different colors on the A1. The Lite version that comes with the A1 doesn’t have an enclosure like the P and X series AMS, but it works in a similar way. Using the packaged software, you can “paint” the surface of your model, and the AMS will feed up to four different colors into your printer to match. This gives you a lot of scope for making prints that look finished without needing to paint them.

I have spent a lot of time using the A1 and A1 Mini with the AMS Lite and packaged together they are incredibly powerful. Like the Mini, the A1 combo feels almost completely plug-and-play in a way that so few printers have before. In all my years of using 3D printers, nothing comes close to the ease of use that comes from these two machines working in tandem. The AMS could stand to be a little more sturdy, and I think the tubes between it and the A1 are too short (it makes it hard to load the filament), but it does work very well at making multicolor prints.

What a waste

James Bricknell/CNET

The A1 Combo’s biggest selling point is also its biggest point of failure. The AMS, when printing multiple colors produces waste. This waste comes from purging the filament so that you get nice transitions between the colors. This produces what is commonly known as “printer poop,” and as you can see, it produces a lot of it. On some prints, the waste outweighs the completed model, and that’s just not sustainable. You can mitigate it by editing the values and maybe printing another model using the purged material, but you’ll never truly get rid of it. If you are printing with PLA, it’s not so bad as it’s biodegradable if you compost it correctly, but any other material is going to create a lot of waste plastic that isn’t going anywhere.

The waste isn’t the biggest issue though. After all, a commercial disposable lid factory will likely make more plastic waste than hobbyist 3D printers could ever hope to generate, but the waste does highlight my least favorite part of the machine: the “poop flinger.”

James Bricknell/CNET

The poop flinger, or waste cutter to give it the proper name, is a pain point in every way. It’s a tiny little blade that is supposed to scrape the filament from the nozzle then a spring flings the bundle away to the left side of the machine. Not only is this messy if you don’t have a pot to catch it, but it’s also effective maybe only 60% of the time. The other 40% of the time, the waste sticks to the nozzle and either gets caught on the purge tower — another waste block that’s required to color print on the A1 — or on the model itself. Having plastic where it shouldn’t be is the major cause of layer shifts and fails and equates to almost all of my frustration with the A1.

The model you can see in the image here was supposed to have four colors: pink, claret, gold and marble for the moon. Because the poop flinger is unable to correctly clear the filament it kept knocking over the purge tower or causing layer shifts in the model itself. By the time I managed to get a complete model, I had used three-quarters of two of the colors and about a quarter each of the other two. That’s around 2 kilograms, or 4 pounds, of material to make this one 250-gram model. It was enormously frustrating.

Still the best despite the issues

The problems highlighted above are frustrating, but not enough to change my outlook on this machine. Like the A1 Mini Combi before it, the A1 Combo is a 3D printer that you can’t help but admire. It’s the bridge between those of us who love to tinker and already enjoy the 3D printing space and those who want to try 3D printing without all of the finicky engineering that goes along with it. With the A1 Combo, you can have stunning prints with very little effort at a price that’s worth every penny.

>>> Read full article>>>

Copyright for syndicated content belongs to the linked Source : CNET – https://www.cnet.com/tech/computing/bambulab-a1-review-as-close-to-perfect-as-ive-ever-used/#ftag=CAD590a51e