It has been touted as a viable way to meet the world’s growing food needs while causing far less harm to the planet than traditional farming.

While lab-grown food might seem like science fiction, researchers here in New Zealand are already making massive gains in creating meat and dairy products in the lab.

The products are becoming increasingly sophisticated – petri dish quail parfait, anyone?

But how do the products stack up nutritionally? What risk do they pose to New Zealand’s agriculture sector? And will the ick factor put people off?

Checkpoint went behind the microscope.

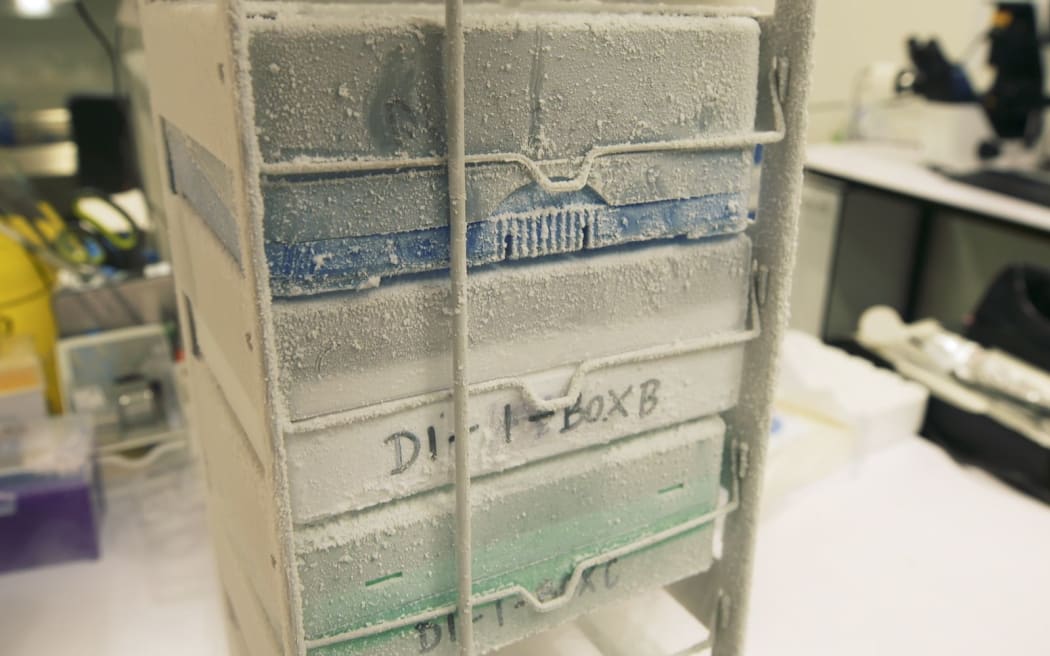

A cloud of liquid nitrogen spilled out as several tubes filled with pinky liquid were pulled from a large cylinder kept at minus -196C at Opo Bio’s Newmarket lab. Believe it or not, the tubes contain thousands of meat cells that are the building blocks of a future burger or sausage, a process known as cultivated meat.

Since launching in 2022, the company has been preparing so-called seeds which are used to grow “real” meat products.

Chief scientist Laura Domigan said while some companies take biopsies from live animals to get the cells, they take a sample from dead livestock supplied by farmers.

Opo Bio supplies the seeds to overseas cultivated meat producers, such as Sydney-based cultured meat company Vow, who grow them in bioreactors – big tanks like those used in beer brewing.

Opo Bio chief scientist Laura Domigan.

Photo: Nick Monro / RNZ

The challenge, Domigan said, is making something appetising.

“For example, Vow has done an approach that’s quite different in that they’re going for a really high-end product, so they do a quail parfait, compared to say some of the other companies like Eat Just in Singapore who are doing like a chicken nugget.”

At the moment only the US and Singapore have signed off to serve up the cultivated meat products, but Food Safety New Zealand and Australia is currently considering an application to bring it to New Zealand.

Asked if the cultivated meat stacked up to a steak from the supermarket nutrition-wise, Domigan said “it should because it comes from the same starting material”.

“Where we’re at currently is that there haven’t been large-scale nutritional analysis done.”

Meat cells out of the dry ice kept at minus -196C.

Photo: Nick Monro / RNZ

Steve Flint, professor of microbiology and food safety at Massey University, said crucial vitamins like B12 could be missing from cultivated meat.

Flint said the idea of meat grown in a lab might put people off, along with its price if it is not affordable.

“Particularly in, you know, today’s environment where the economy is not doing well and people are trying to get by as best they can, they are going to go for the cheapest source of nutrition.”

Opo Bio is not the only start-up exploring the possibilities of lab-grown food. Since 2021, Daisy Lab in Parnell has been creating proteins contained in dairy products through precision fermentation.

It is a refined form of brewing, but instead of beer, co-founder Emily McIsaac said it brews protein.

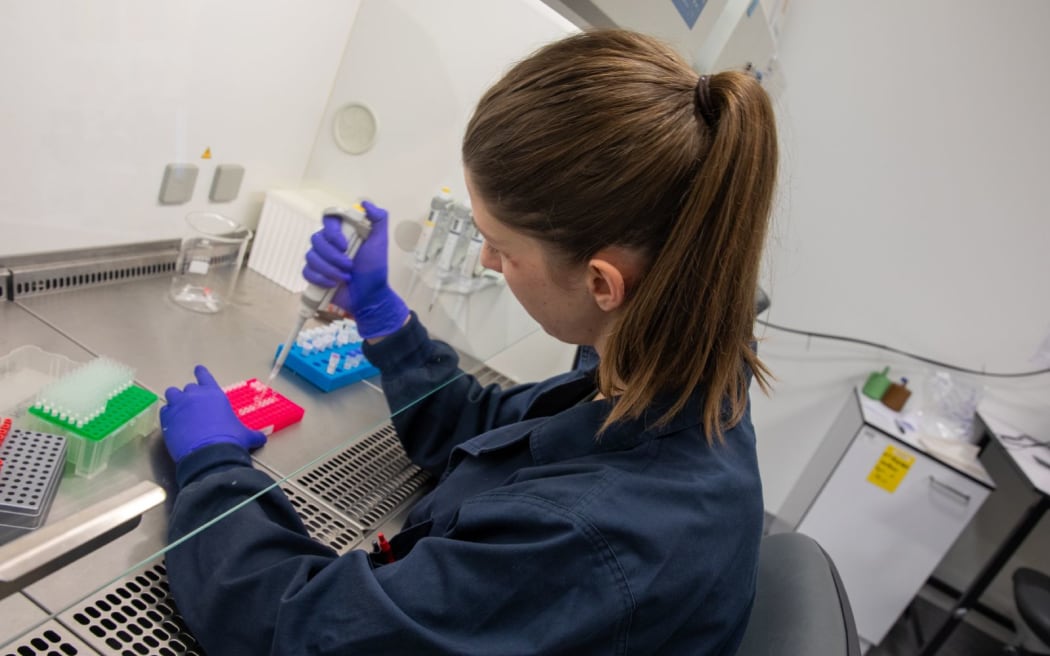

Laboratory work at Opo Bio.

Photo: Nick Monro / RNZ

“We’re not producing whole milk the way that it comes out of a cow – that is a very complex liquid, a cow does that better than anything else ever could. But we can produce those individual proteins, which is what New Zealand really is in the industry of producing anyway.

“Most of our exports are milk proteins or dried-down milk powder, rather than whole milk.”

Flint said producing proteins like lactoferrin, which are found in milk, could have a big benefit for the food industry.

“If you could make it economically, then yes, it’s an ingredient that we already have a need for – but it could be made more successfully using precision fermentation.”

Daisy Lab has been granted approval by the Environmental Protection Authority to ramp up its research 500-fold.

Its scientists have plans to collaborate with food producers to create products like ice creams, yoghurts and cheeses, ultimately getting them into supermarkets.

A worker at Opo Bio’s lab in Newmarket, Auckland.

Photo: Nick Monro / RNZ

Daisy Lab co-founder Emily McIssac said the process reaps benefits for the environment.

“Precision fermentation offers a reduction in greenhouse gas emissions, water use, land use amongst other things. It’s nutritionally identical without the environmental or ethical consequences of dairy farming.”

Domigan echoed this enthusiasm.

“We believe it’s an and, not an or. We have good relationships with a number of New Zealand farmers and that’s actually where we source our starting material.

“We need to diversify as well… New Zealand can’t produce more meat than it already does. We can try and command a higher price, but we really need to bring in new technologies as well.”

>>> Read full article>>>

Copyright for syndicated content belongs to the linked Source : RNZ – https://www.rnz.co.nz/news/national/521112/behind-the-scenes-at-a-lab-meat-factory-in-auckland