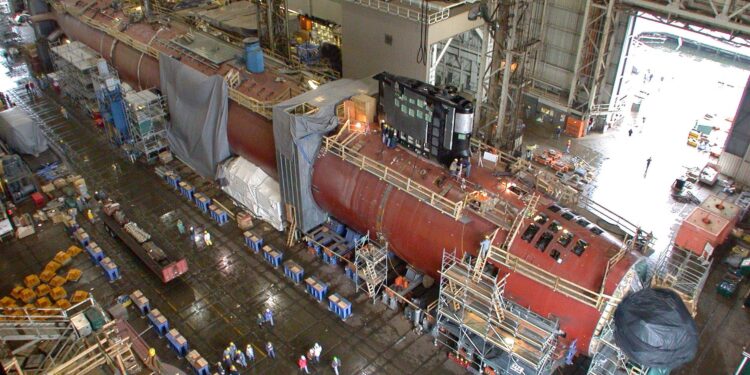

In an ambitious leap toward revolutionizing naval engineering, the ARM Institute has announced a new technology project call aimed at accelerating submarine manufacturing. As the demand for advanced underwater vessels grows, this initiative seeks to harness cutting-edge innovations to streamline production processes, reduce costs, and enhance efficiency. By fostering collaboration among industry leaders, researchers, and technology developers, the ARM Institute hopes to propel the submarine manufacturing sector into a new era of rapid, precision-driven development-setting the stage for the next generation of maritime defense capabilities.

Unlocking Innovation The ARM Institute Seeks Advanced Technologies for Submarine Production

In a bid to revolutionize the defense sector’s manufacturing landscape, the ARM Institute is calling for innovative technology submissions that can accelerate submarine production. This initiative targets cutting-edge solutions in robotics, automation, and digital twin technologies to streamline complex assembly processes, reduce lead times, and enhance precision. By fostering collaboration between industry leaders, academic researchers, and startups, the ARM Institute aims to build a robust ecosystem ready to tackle the unique challenges of undersea vehicle fabrication.

Key technology focus areas include:

- Advanced robotics for high-precision welding and assembly

- AI-driven process optimization and predictive maintenance

- Integrated 3D visualization and digital twin modeling

- Smart sensor networks for quality assurance and real-time monitoring

| Technology | Expected Impact | Development Stage |

|---|---|---|

| Collaborative Welding Robots | 50% reduction in assembly time | Prototype |

| AI Quality Control System | Improved defect detection accuracy | Pilot Testing |

| Digital Twin Simulation | Optimized workflow visualization | Conceptual |

Enhancing Efficiency The Role of Automation and Robotics in Accelerating Manufacturing Processes

Incorporating automation and robotics is revolutionizing the manufacturing landscape, particularly in complex industries like submarine production. By leveraging cutting-edge technologies, manufacturers can significantly reduce assembly times, minimize human error, and improve overall product consistency. Automated systems operate with precision and unwavering speed, enabling manufacturers to tackle intricate tasks that once required extensive manual labor. From precision welding to quality inspections, robotics streamline processes that traditionally bottleneck production, pushing boundaries on what is achievable within tight deadlines.

Key benefits driving this transformation include:

- Increased throughput: Robots work continuously without fatigue, accelerating workflow.

- Enhanced precision: Consistent and repeatable actions reduce defects and rework.

- Improved safety: Automation isolates personnel from hazardous environments.

- Data-driven optimization: Integrated sensors collect real-time metrics to refine operations.

| Process | Automation Impact | Time Reduction |

|---|---|---|

| Hull Assembly | Robotic welding & positioning | 30% |

| Component Inspection | AI-powered visual analysis | 45% |

| Material Handling | Autonomous guided vehicles | 25% |

Strategic Recommendations Collaborating for Scalable Solutions in Underwater Vehicle Construction

To accelerate progress in submarine manufacturing, fostering cross-industry collaboration is paramount. Bringing together advanced robotics experts, materials scientists, and naval engineers lays the foundation for innovative approaches that can revolutionize underwater vehicle construction. Strategic partnerships should emphasize scalable solutions that reduce production times, enhance modular design, and improve assembly precision-key factors that will ultimately lower costs and increase deployment speed.

Core strategic recommendations include:

- Integration of automated welding and inspection systems to streamline assembly

- Development of lightweight composite materials tailored for deep-sea durability

- Adoption of modular architecture enabling easy upgrades and maintenance

- Utilization of digital twin technology for real-time performance monitoring

| Recommendation | Expected Impact | Key Stakeholders |

|---|---|---|

| Automated Welding Systems | 30% reduction in assembly time | Robotics firms, Shipbuilders |

| Advanced Composites | 40% weight reduction, improved durability | Materials researchers, Defense Agencies |

| Modular Design | Simplified upgrades and logistics | Systems integrators, Manufacturers |

| Digital Twin Tech | Predictive maintenance, performance insights | Software developers, Operators |

| Recommendation | Expected Impact | Key Stakeholders |

|---|---|---|

| Automated Welding Systems | 30% reduction in assembly time | Robotics firms, Shipbuilders |

| Advanced Composites | 40% weight reduction, improved durability | Materials researchers, Defense Agencies |

| Modular Design | Simplified upgrades and logistics | Systems integrators, Manufacturers |

| Digital Twin Tech | Future Outlook

As the ARM Institute launches its call for innovative technology projects aimed at accelerating submarine manufacturing, the maritime industry stands on the brink of transformative change. By fostering cutting-edge solutions and collaborative expertise, this initiative promises to streamline production timelines and enhance the capabilities of undersea vessels. While challenges remain, the unfolding developments will be ones to watch closely-offering a glimpse into a future where advanced robotics and engineering converge beneath the waves to redefine submarine construction. |