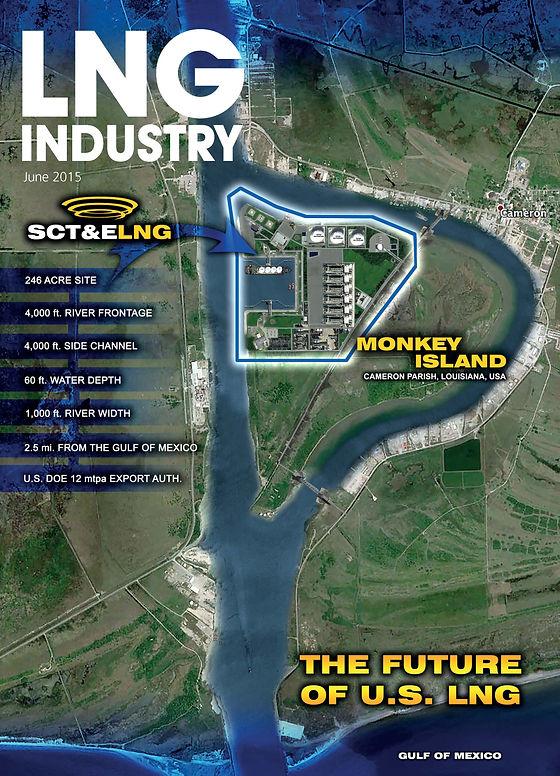

In a strategic move signaling confidence in cutting-edge energy solutions, Monkey Island LNG has selected ConocoPhillips’ liquefaction technology to power its latest venture. This partnership reflects a growing trend in the liquefied natural gas (LNG) sector, where innovation and efficiency drive project success amidst evolving market dynamics. As Monkey Island LNG advances its ambitions, the choice of ConocoPhillips’ proven technology underscores a commitment to reliability and operational excellence in an increasingly competitive landscape.

Monkey Island LNG Selects ConocoPhillips Technology to Enhance Liquefaction Efficiency

In a strategic move to boost production efficiency, Monkey Island LNG has incorporated ConocoPhillips’ cutting-edge liquefaction technology into its operations. This integration promises to optimize the liquefaction process, reducing energy consumption while increasing output reliability. By adopting ConocoPhillips’ proprietary solutions, the facility is set to enhance its operational performance, aligning with the industry’s push towards more sustainable and cost-effective LNG production methods.

The partnership is expected to deliver several key benefits, including:

- Improved thermal efficiency to reduce fuel usage and emissions

- Increased throughput capacity for meeting growing energy demands

- Advanced control systems that enable real-time process optimization

- Reduced maintenance requirements through innovative design features

| Feature | Benefit | Impact |

|---|---|---|

| Optimized Heat Exchangers | Higher energy recovery | Lower operational costs |

| Smart Control Algorithms | Enhanced process stability | Consistent LNG quality |

| Modular Design | Easy scalability | Adaptability for future expansions |

Evaluating the Impact of Advanced Liquefaction on Project Performance and Sustainability

The integration of ConocoPhillips’ advanced liquefaction technology at Monkey Island LNG marks a significant leap forward in optimizing both project performance and environmental stewardship. By leveraging state-of-the-art process designs and cutting-edge materials, the facility is poised to achieve higher efficiency levels, translating into lower operational costs and reduced greenhouse gas emissions. This technology not only improves the liquefaction rate but also enhances plant reliability, ensuring consistent output even under variable feed gas conditions. As a result, the project benefits from increased resilience against market fluctuations and regulatory pressures.

From a sustainability perspective, the new liquefaction system is designed with energy conservation and emissions mitigation at its core. Key features include:

- Reduced energy consumption through optimized refrigerant cycles

- Lower methane slip by integrating advanced sealing solutions

- Modular design that facilitates quicker installation and minimizes onsite environmental impacts

These benefits contribute to the project’s overall carbon footprint reduction targets, aligning with global trends toward cleaner energy production. The combination of performance gains and sustainability advances underscores the transformative impact advanced liquefaction technologies have on the future of LNG projects.

| Performance Metric | Traditional Tech | ConocoPhillips Tech |

|---|---|---|

| Energy Efficiency | 85% | 92% |

| CO2 Emissions Reduction | Baseline | 15% Lower |

| Startup Time | 48 Hours | 36 Hours |

| Methane Slip | 0.5% | 0.2% |

Strategic Considerations for Integrating Cutting-edge LNG Solutions in Future Developments

When integrating avant-garde LNG technologies into upcoming projects, decision-makers must evaluate not only operational efficiency but also long-term sustainability and scalability. Leveraging ConocoPhillips’ proven liquefaction technology offers a strategic advantage through enhanced thermal efficiency and modular design flexibility, making it easier to adapt to fluctuating market demands. Companies are urged to adopt a holistic approach, incorporating environmental considerations-such as reducing greenhouse gas emissions-and compliance with evolving regulatory frameworks to future-proof their investments. Prioritizing partnerships with technology providers that emphasize innovation and environmental stewardship can accelerate project timelines and reduce unforeseen risks.

- Energy efficiency: Lower power consumption per unit of LNG produced

- Modularity: Streamlined facility expansion capability

- Emission control: Integration of carbon capture and storage (CCS) options

- Robust supply chain: Ensures availability of critical components and maintenance support

| Key Metric | Industry Standard | ConocoPhillips Technology |

|---|---|---|

| Thermal Efficiency | 89% | 94% |

| Modular Units | 4 | 6+ |

| CO2 Emissions (kg/ton LNG) | 450 | 320 |

Beyond technical metrics, strategic integration calls for a robust project management framework that fosters collaboration between engineering teams, technology partners, and local stakeholders. Early-stage risk assessment and ongoing performance monitoring are essential to mitigate disruptions and ensure operational excellence. Additionally, aligning project goals with emerging energy transition trends-such as hydrogen blending and digitalization-positions developments to capitalize on future revenue streams and evolving regulatory incentives. The blend of innovation, adaptability, and sustainability not only enhances project viability but also strengthens the operator’s competitive edge in the global LNG market.

The Way Forward

As Monkey Island LNG sets its sights on a future powered by ConocoPhillips’ proven liquefaction technology, the project embodies a significant stride in advancing energy infrastructure with efficiency and reliability at its core. This collaboration not only underscores the strategic importance of cutting-edge solutions in meeting growing global demand but also highlights the evolving landscape of LNG development. As the industry watches closely, Monkey Island LNG’s journey promises to be a noteworthy chapter in the story of energy innovation and sustainable growth.