As demand for lithium-ion batteries soars-driven by the rapid expansion of electric vehicles and renewable energy storage-the strain on global supply chains has never been greater. In response, a groundbreaking study published in Nature highlights a circular economy approach as a viable solution to reduce environmental impact, secure critical materials, and promote sustainable growth. This innovative strategy emphasizes recycling, reuse, and design optimization to transform how raw materials are sourced and batteries are manufactured, used, and disposed of, heralding a new era for the global lithium-ion battery industry.

Rethinking Resource Use in the Lithium-ion Battery Lifecycle

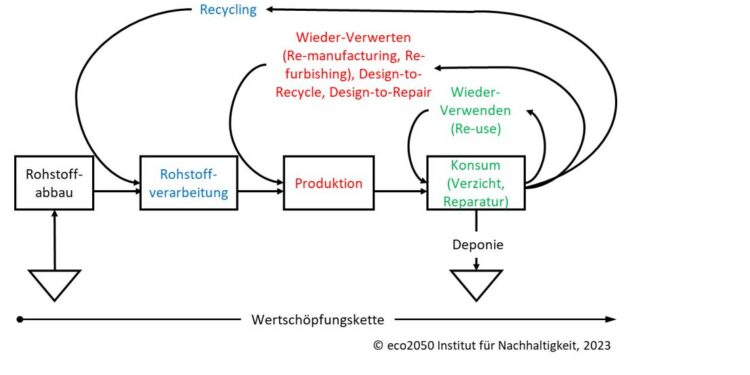

Current practices in the lithium-ion battery supply chain focus heavily on extraction and manufacturing phases, often sidelining the potential embedded in end-of-life batteries. Embracing a circular economy calls for a fundamental shift – from linear consumption to systemic resource stewardship. This means maximizing the recovery, reuse, and recycling of critical materials such as lithium, cobalt, and nickel, thereby reducing reliance on virgin mining. Innovative recycling technologies and improved battery design can dramatically enhance material retention, cutting down waste and environmental footprints.

Industry leaders and policymakers are exploring collaborative frameworks to improve transparency and resource tracking throughout the battery lifecycle. Key strategies include:

- Standardizing batteries for easier disassembly and material recovery

- Implementing take-back and refurbishment programs at scale

- Investing in cutting-edge hydrometallurgical and direct recycling methods

| Resource | Primary Extraction Impact | Recycling Potential |

|---|---|---|

| Lithium | High water usage, habitat disruption | Up to 90% recovery efficiency |

| Cobalt | Ethical concerns, supply risk | 75%-85% recovery rates |

| Nickel | Energy-intensive mining | 80% recovery via hydrometallurgy |

Advancing Recycling Technologies to Drive Supply Chain Sustainability

Breakthroughs in recycling technologies are reshaping the lithium-ion battery supply chain, positioning sustainability at the forefront of global efforts to reduce environmental impact. Innovative processes such as hydrometallurgical and direct recycling are dramatically improving the recovery rates of critical metals like lithium, cobalt, and nickel, reducing the dependence on virgin mining. These advanced techniques not only minimize waste but also significantly lower the carbon footprint of battery production, enabling manufacturers to close the loop with a truly circular model.

Key advancements include:

- Enhanced material purity recovery, boosting battery performance and lifespan

- Lower energy consumption in recycling operations compared to traditional smelting

- Increased scalability of recycling facilities driven by modular and automated systems

- Integration of AI and machine learning for efficient material sorting and process optimization

| Technology | Recovery Rate | Energy Use | Environmental Impact |

|---|---|---|---|

| Hydrometallurgical | 95% | Low | Minimal emissions |

| Direct Recycling | 85% | Very Low | Reduced waste |

| Pyrometallurgical | 75% | High | Higher emissions |

Policy Recommendations for a Resilient and Circular Battery Economy

To advance a sustainable lithium-ion battery ecosystem, policymakers must prioritize integrated frameworks that foster circularity throughout the entire supply chain. This includes incentivizing the development of robust recycling infrastructures capable of recovering critical materials with high efficiency, and promoting design innovation that emphasizes modularity and ease of disassembly. Encouraging transparency via traceability technologies can ensure ethical sourcing and minimize environmental impacts from mining practices. Furthermore, adopting extended producer responsibility (EPR) schemes will bind manufacturers to the end-of-life management of batteries, closing the loop between production and reuse.

Strategic collaboration between governments, industry stakeholders, and research institutions is essential to harmonize regulations and standards worldwide, avoiding fragmentation that hinders scale-up efforts. Key focus areas should incorporate:

- Subsidies for second-life battery applications, extending product utility and reducing demand for virgin materials.

- Investment in advanced sorting and chemical recovery technologies to increase yield and lower environmental footprints.

- Development of clear metrics and reporting frameworks to measure circularity progress and guide continuous improvement.

| Policy Action | Expected Impact |

|---|---|

| EPR Implementation | Higher recycling rates, reduced landfill waste |

| Design for Disassembly Mandate | Improved material recovery efficiency |

| Second-Life Battery Incentives | Extended product lifespan, reduced raw material demand |

| Global Standards Alignment | Seamless cross-border battery trade |

Final Thoughts

As the demand for lithium-ion batteries continues to surge, driven by the global shift toward clean energy and electric mobility, adopting a circular economy approach emerges as a critical strategy for sustainability. The insights highlighted in Nature underscore the need for enhanced recycling technologies, resource recovery, and collaborative supply chain practices to reduce environmental impact and secure material availability. Moving forward, policymakers, manufacturers, and researchers must work in unison to transform the lithium-ion battery supply chain into a resilient and regenerative system-one that not only powers innovation but also safeguards the planet for future generations.