Features, Editors’ Blog, Interviews, Long Reads

Features, Editors’ Blog, Interviews, Long Reads

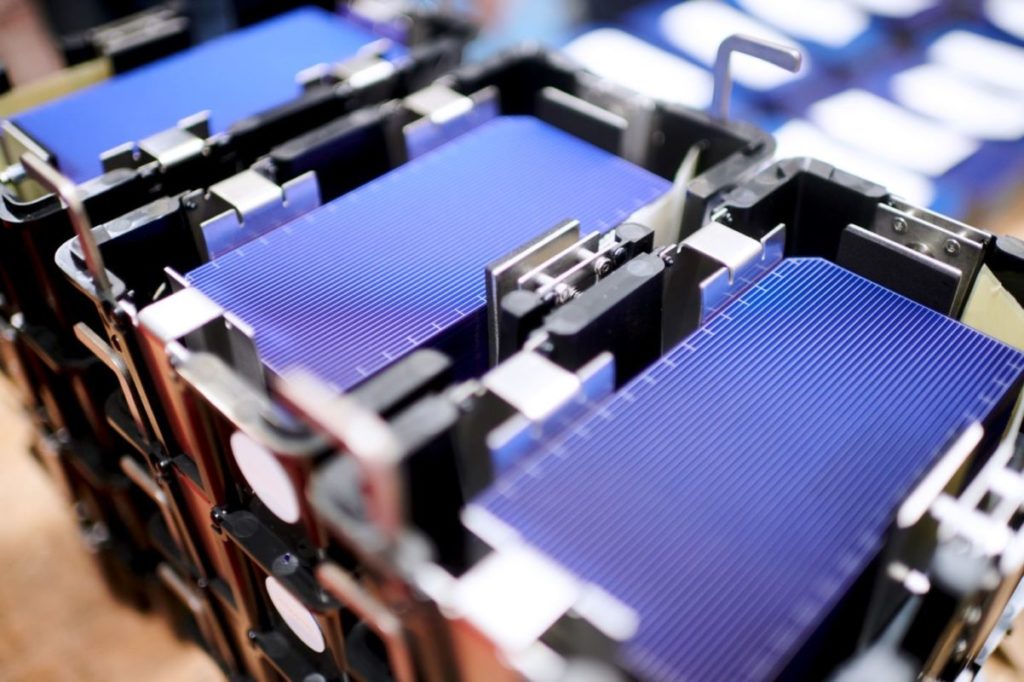

Highland Materials president Richard Rast told PV Tech Premium that there is an “opportunity for innovation” in the US manufacturing sector. Image: Meyer Burger

Highland Materials president Richard Rast told PV Tech Premium that there is an “opportunity for innovation” in the US manufacturing sector. Image: Meyer Burger

New entrants into the US polysilicon manufacturing space could be a “game changer” for the US solar sector, Solar Media head of research Finlay Colville told PV Tech Premium this week.

Colville spoke to PV Tech Premium about Highland Materials’ receipt of US$256 million in tax credits to build a polysilicon manufacturing facility in Tennessee, with Highland Materials president Richard Rast noting that there is an “opportunity for innovation” in the US manufacturing sector.

This article requires Premium SubscriptionBasic (FREE) Subscription

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

Regular insight and analysis of the industry’s biggest developments

In-depth interviews with the industry’s leading figures

Unlimited digital access to the PV Tech Power journal catalogue

Unlimited digital access to the Photovoltaics International journal catalogue

Access to more than 1,000 technical papers

Discounts on Solar Media’s portfolio of events, in-person and virtual

Or continue reading this article for free

Highland Materials first announced the award of the tax credits in April, as part of a wave of investment into more than 100 projects to accelerate clean energy manufacturing and recycling in industrial facilities in the US. This is particularly significant for the polysilicon sector in particular, and the solar industry more broadly, as China has come to dominate global polysilicon production, with Chinese-made products accounting for 79.4% of the world’s polysilicon in 2021, up from 28.6% a decade earlier.

Last month, a group of solar manufacturers investing in the US sector, calling itself the Solar Energy Manufacturers for America (SEMA) Coalition, called on the government to address this imbalance. The SEMA Coalition suggested the US solar supply chain has “glaring gaps,” which have left US-based manufacturers at a disadvantage.

Rast also told PV Tech Premium that Highland Materials will be using a new manufacturing process at the facility, which he dubbed a “naturally occurring process of segregation,” the latest adjustment to the solar manufacturing process.

To read the full analysis of Highland Materials’ plans and their significance for US solar manufacturing, visit PV Tech Premium here.

PV Tech has been running PV ModuleTech Conferences since 2017. PV ModuleTech USA, on 21-22 May 2024, will be our third PV ModulelTech conference dedicated to the U.S. utility scale solar sector. The event will gather the key stakeholders from solar developers, solar asset owners and investors, PV manufacturing, policy-making and and all interested downstream channels and third-party entities. The goal is simple: to map out the PV module supply channels to the U.S. out to 2025 and beyond.

San Francisco Bay Area, USA

PV Tech has been running an annual PV CellTech Conference since 2016. PV CellTech USA, on 8-9 October 2024 is our second PV CellTech conference dedicated to the U.S. manufacturing sector. The event in 2023 was a sell out success and 2024 will once again gather the key stakeholders from PV manufacturing, equipment/materials, policy-making and strategy, capital equipment investment and all interested downstream channels and third-party entities. The goal is simple: to map out PV manufacturing in the U.S. out to 2030 and beyond.

Features, Editors’ Blog, Interviews, Long Reads

>>> Read full article>>>

Copyright for syndicated content belongs to the linked Source : PV Tech – https://www.pv-tech.org/highland-materials-us-silicon-production-game-changer-us-solar/