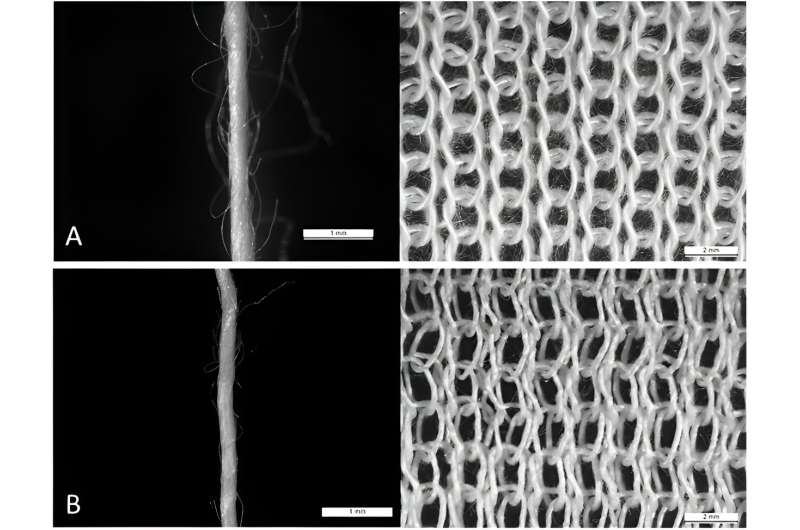

Image: Comparison of yarn hairiness for yarns of the same linear density (30 tex) and different spinning systems. Credit: Source: ‘Investigating the influence of yarn characteristics on microfibre release from knitted fabrics during laundering’. Can be used without credit.

New research in Frontiers of Environmental Science sheds light on how manufacturing choices influence microfiber release in textiles.

Using a washing simulator (gyrowash), the researchers from the University of Leeds tested various densities of yarns in unknitted hanks and knitted forms, and compared how much microfiber they released when washed.

Alice Hazlehurst, doctoral researcher in the School of Design at the University of Leeds, who led the research, said, “Our findings show that the entire process of textile production, down to the way yarn is spun, is important in the effort to limit microfiber release.

“Manufacturers should contain these details in specifications of yarn spinning, as well as the fiber type, to help clothing designers make more informed choices.”

Their key findings were:

Unknitted polyester released more microfiber than unknitted cotton, but similar amounts were released when polyester was knitted. This suggests that polyester suffered less damage than cotton during the knitting process.

Microfiber release in tightly knitted fabrics during laundering was reduced, but manufacturers should consider fiber fly—the visible ‘fluff’ that comes off fabrics as they are knitted in factories—which is higher when garments are tightly knitted.

Vortex-spun yarns (where fibers are twisted using jets of air in a vortex) had a lower microfiber release than ring-spun yarns (where fibers are twisted in a metal ring). Ring-spun yarns tend to be more ‘hairy’ than vortex-spun yarns, which has been shown to increase microfiber release in washing.

The research concluded that changes to the fiber composition and the yarn spinning system would have the greatest influence in terms of reducing microfiber release.

However, these details are not currently included in product specifications, which makes it more difficult for brands to make informed choices about which garments will release more or less microfiber.

More research needed

The academics are also calling for more research into the effects of microfiber release on the environment and human health so measures can be targeted towards reducing harm.

Dr. Mark Taylor, Research Fellow at Leeds’ School of Design, said, “We know cotton produces more microfiber than polyester and people assume that cellulose (from cotton) is less worrying than microplastic because it’s natural. But the truth is that we don’t have enough information about the impacts of these fibers on humans, aside from knowing they can take hundreds of years to biodegrade and can have a negative impact on marine life.”

Dr. Mark Sumner, Lecturer in Sustainable Fashion at the School of Design, said, “Our previous research found that UK washing is a huge source of pollution, releasing an estimated 1,500 double decker buses worth of microfiber every year, so it’s important that information about fabric knitting and yarn spinning systems are included in specifications.”

More information:

Alice Hazlehurst et al, Investigating the influence of yarn characteristics on microfibre release from knitted fabrics during laundering, Frontiers in Environmental Science (2024). DOI: 10.3389/fenvs.2024.1340229

Citation:

How do manufacturing choices affect microfiber shed? (2024, April 5)

retrieved 6 April 2024

from https://phys.org/news/2024-04-choices-affect-microfiber.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.

>>> Read full article>>>

Copyright for syndicated content belongs to the linked Source : Phys.org – https://phys.org/news/2024-04-choices-affect-microfiber.html