Unleashing Innovation Through Spotfire Visual Data Science

In a world where data is pivotal to strategic decision-making, the capacity to convert unrefined data into actionable insights has become increasingly vital. Businesses across various sectors are striving to utilize sophisticated analytics to enhance operational efficiency, improve product quality, and stimulate innovation. Within this context, TIBCO’s Spotfire emerges as a formidable asset in visual data science, providing manufacturers with an exceptional platform that not only visualizes their data but also reveals significant patterns and trends. This article examines how Spotfire is transforming the manufacturing industry by enabling companies to harness the vast amounts of information they generate, thereby driving innovation and sustaining a competitive advantage in an ever-changing market landscape. Join us as we investigate the profound effects of Spotfire through case studies, expert perspectives, and emerging trends that highlight its influence on modern manufacturing.

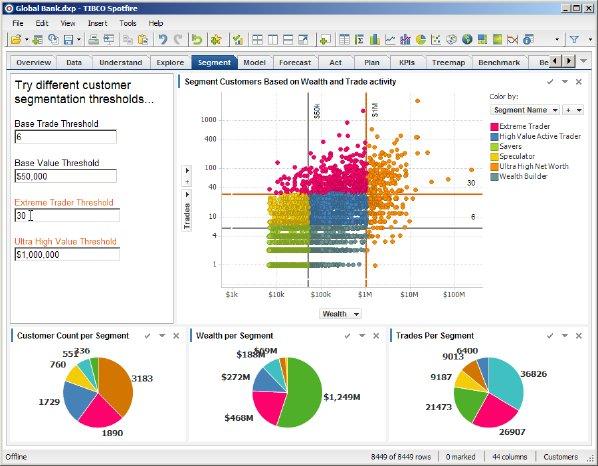

Spotfire Visual Data Science Reveals Insights for Manufacturing Productivity

As data becomes increasingly integral to achieving excellence in manufacturing, Spotfire Visual Data Science stands out as a revolutionary tool that empowers organizations to tap into analytics effectively. By utilizing captivating visualizations and user-friendly data exploration features, manufacturers can discover patterns and gain valuable insights. These revelations inform decisions that optimize operations and boost productivity. For example, Spotfire enables teams to:

- Detect inefficiencies: Visual analytics assist in identifying production line bottlenecks.

- Maximize resource utilization: Ensure optimal deployment of materials and workforce.

- Avert maintenance issues: Predictive analytics forecast equipment failures before they arise.

The incorporation of machine learning algorithms within Spotfire’s framework further enhances its potential for fostering innovation within manufacturing processes. By automating analytical tasks, manufacturers can concentrate on strategic initiatives rather than becoming overwhelmed by raw numbers. For instance, organizations employing Spotfire have reported significant advancements in their ability to:

- Improve product standards: Continuous feedback mechanisms facilitate real-time adjustments during production.

- Shrink time-to-market: Swift analysis leads to faster decision-making capabilities responsive to market needs.

- Curtail operational expenses: strong > Streamlined processes minimize waste while maximizing efficiency—benefiting overall profitability. li >

Leveraging Predictive Analytics for Production Innovation

The contemporary manufacturing environment demands leveraging predictive analytics strong >as an essential strategy for promoting innovation while enhancing production efficiency. By scrutinizing historical datasets and recognizing trends , businesses can not only foresee equipment malfunctions but also fine-tune production timelines while minimizing waste . This proactive methodology empowers manufacturers with informed decision-making capabilities , timely interventions , ultimately boosting productivity . Insights derived from data enable teams refine processes ensuring optimal performance along production lines . p >

Additionally , integrating visual data science strong > tools like Spot fire is reshaping how teams interpret information within the manufacturing domain . With dynamic visuals at their disposal , stakeholders can easily grasp intricate datasets identify patterns share findings seamlessly across departments . The following highlights key advantages associated with adopting such technologies : p >

-

< li >< strong > Improved Collaboration : strong > Teams engage more effectively through visually represented findings . li >

< li >< strong > Accelerated Decision-Making : strong >Visual insights hasten identification actionable items . li >

< li >< strong > Enhanced Accuracy : strong > Precise visualizations diminish risks misinterpretation errors .

li >

ul >

Equipping Decision-Makers with Instantaneous Data Visualization Tools

Navigating today’s fast-paced manufacturing landscape necessitates access real-time insights for informed choices making decisions requires access real-time insights.

Spot fire’s advanced visualization tools play crucial role helping companies bridge gap between extensive volumes raw information actionable intelligence.

By converting complex datasets intuitive interactive visuals leaders quickly discern trends anomalies empowering them respond promptly market demands operational challenges.

This capability not only boosts productivity fosters culture driven by insight where innovations emerge keeping operations ahead competition.

The standout features offered by spot fire which empower leaders include : p >

-

< li >< strong>Dynamically Updating Dashboards: Tailored visuals refresh instantly providing comprehensive overview key performance indicators.

Strong > Li >

< Li >< Strong>Predictive Analytics: Tools forecasting upcoming disruptions allowing proactive strategies.

< / Strong > Li >

< Li >< Strong Collaboration Features: Enable seamless sharing insights among diverse departments ensuring alignment collective problem-solving. < /Strong >

Here’s snapshot showcasing successful integration spot fire workflows:

| Name of Company | Description of Innovation Capability | Tangible Impact Achieved (%)< / th > < tr /> |

|---|---|---|

| Name A Manufacturer | Real-Time Quality Control | 30% Reduction Defects |

| Name B Manufacturer | Predictive Maintenance td/ td style= “text-align:left;”>15% Savings Downtime td/ | |

| Name C Manufacturer td/ td style= “text-align:left;”>Supply Chain Optimization td/ td style= “text-align:left;”>20% Improvement Efficiency td/ |

Looking Ahead: The Future Pathway Forward

The adoption spot fire visual science represents transformative leap forward towards enhanced efficiencies innovations throughout sector.

Harnessing power advanced visualization techniques coupled robust analytic frameworks allows firms streamline operations cultivate culture continuous improvement adaptability necessary thrive evolving landscapes characterized influx bigdata emerging techs .

As industries progress navigating complexities inherent modernity leveraging insightful knowledge will prove indispensable maintaining competitive edge moving forward .

With instruments like spot fires at disposal enterprises aren’t merely reacting shifts occurring marketplace; instead proactively shaping future trajectory field itself!

As we gaze toward horizon ahead it becomes evident centrality datadriven methodologies will underpin successful strategies paving way new era growth prosperity!